How to Implement an Operation Warp Speed for Rare Earths

The US government must respond to far-reaching Chinese export controls on rare earth elements mining and processing, but it faces a choice between two approaches.

The US government must respond to far-reaching Chinese export controls on rare earth elements mining and processing, but it faces a choice between two approaches.

This is a joint report published with Institute for Progress

Arnab Datta is Managing Director of Policy Implementation at Employ America

Saif Khan is Distinguished Technology Fellow at IFP

Tim Hwang is Senior Technology Fellow at IFP

Tim Fist is Director of Emerging Technology Policy at IFP

China has instituted far-reaching controls on rare earth exports to every country in the world, exploiting its global dominance in rare earth elements mining and processing. Many of these controls are extraterritorial — they apply to rare earth products made anywhere in the world, as well as to the manufacturing tools, technical information, and support from Chinese nationals needed to make these products. Given the ubiquitous role of rare earths in most high-tech supply chains, the potential impact is extraordinary. China is likely using these controls to gain leverage in trade negotiations, retaliate against American restrictions, degrade American and allied technological capabilities, and potentially even to entrench its dominance in downstream rare earth-dependent manufacturing supply chains.

The US government must respond, but it faces a choice between two approaches:

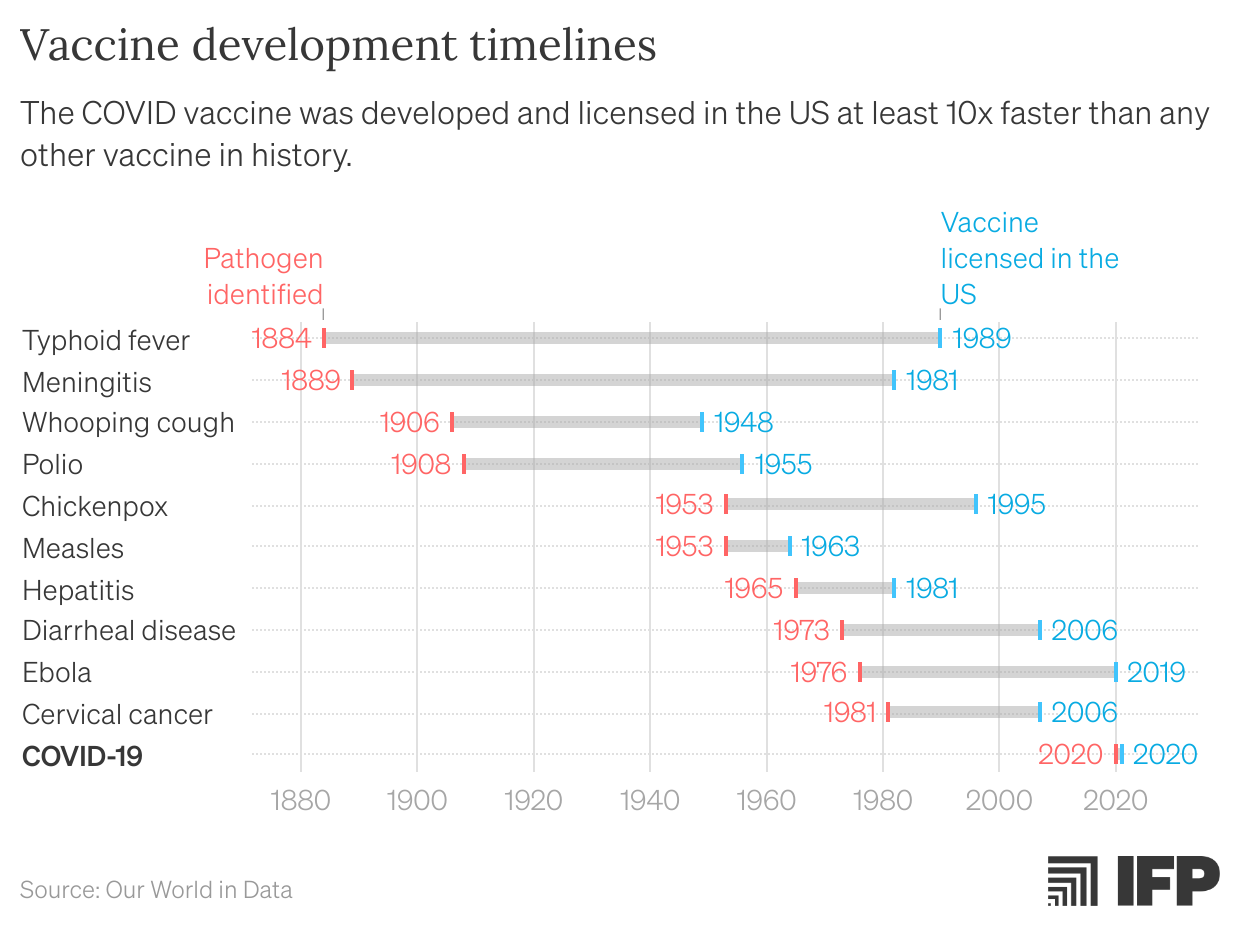

When faced with the catastrophic public health emergency presented by the coronavirus pandemic in 2019, the Trump administration’s Operation Warp Speed marshaled a variety of policy levers — purchase guarantees, regulatory streamlining, and whole of government commitment — to deliver the first COVID vaccine in just 9 months, more than 10x the normal speed, and far faster than any vaccine ever developed.

The success of Operation Warp Speed teaches us how to effectively execute a high urgency, lightning-speed government initiative. The Warp Speed model can be applied to rare earths by establishing clear predetermined targets to structure competition and creating incentives for the market by incentivizing scaled production.

Investment in rare earths faces compounding uncertainties: volatile prices, Chinese control of market infrastructure, and decade-long permitting processes with litigation risk. Similarly, vaccine markets chronically underinvest in pandemic preparedness because episodic demand and pricing pressure don't reward building 'insurance capacity.' Both are market failures requiring strategic government intervention.

We have everything at our disposal to deal with the threat. America and its partners have the mineral resources necessary for a self-reliant supply chain. We know that only a non-traditional toolkit will address the market challenges. The Trump administration recently deployed many parts of this toolkit in its recent deal with MP Materials to expand the company’s mining, processing, and magnet manufacturing activities.

As Treasury Secretary Scott Bessent has called for, America needs a new Operation Warp Speed to secure our rare earths supply chain. A Warp Speed for rare earths should marshal a coordinated, whole-of-government effort to secure America’s rare earth supply chain. It must rest on four pillars:

Together, these steps would create a structure that scales domestic capacity, aligns allied partners, and builds the financial and regulatory architecture needed to outcompete China’s command over critical minerals.

This brief offers a summary of the challenges that have held us back, and a more detailed description of what an Operation Warp Speed for rare earths should include.

The United States does not suffer from a lack of mineral resources, but from a lack of liquidity, risk intermediation, and timely permitting to make mining and processing financeable at scale. Without these measures, rare earths mining and processing is difficult in the US, as both steps require significant upfront capital, and steady revenues can take years to materialize.

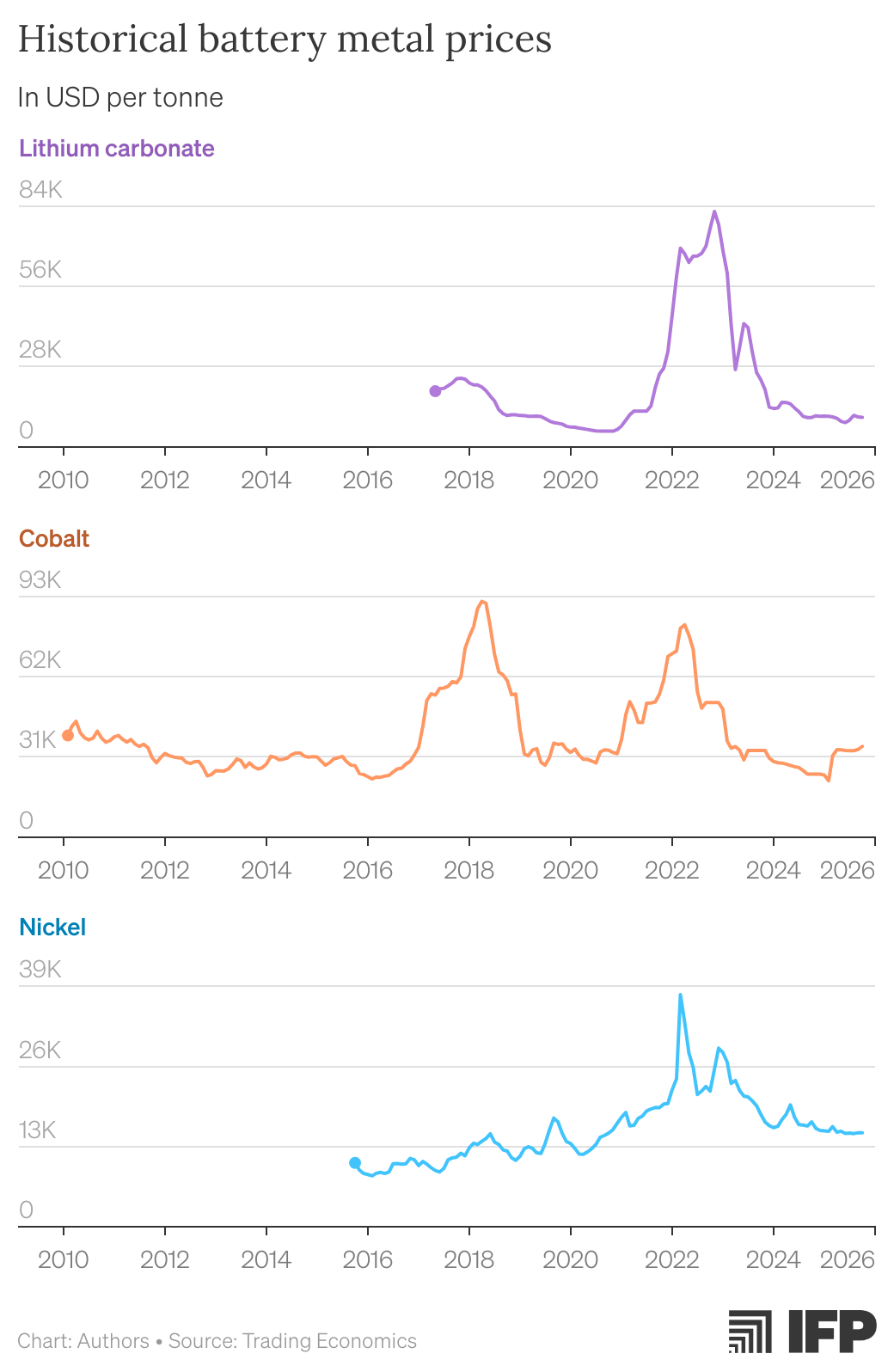

Extreme volatility in rare earths makes investment in new production capacity risky. Prices can swing, sometimes even more violently than they do for oil and gas. For example, a key lithium benchmark lost nearly 90% of its value in the past three years. Neodymium oxide, a key magnet material, has swung between $39.50/kg and $193.75/kg since the start of 2020. Expanding rare earth production capacity takes months to years, so the necessary investments must be made under conditions of strong uncertainty about prices at the time new production comes online. For producers and processors,[1] this creates asymmetric risk that disfavors new investment. If they produce too little when demand is high, they just miss out on some profits. But if they make too much when demand is low, they can go bankrupt from overinvesting. That asymmetry deters the investment we need to expand supply.

China’s dominance also means domestic and allied producers and processors are especially vulnerable to their policy actions. As an example, consider the lithium market over the past decade. Following the Thirteenth Five-Year Plan in 2016, the Chinese government implemented a massive set of subsidies to spur lithium processing as part of an effort to spur more electric vehicle production. An investment boom followed, and miners across the world took advantage. In 2019, however, the Chinese government dramatically scaled back these subsidies. When Chinese purchasers reneged on bilateral contracts signed with the expectation of continued subsidies, Canadian and Australian miners suddenly found themselves with no ready market for their products. Without financial market participants to take positions on the price of lithium, revenues fell, and producers defaulted with mines only partially built or put on “care and maintenance,” a costly, often open-ended temporary mine closure. The excess supply led to a 60% price decrease and helped drive the bankruptcies of companies like Alita and Nemaska, producers from Australia and Canada, respectively.

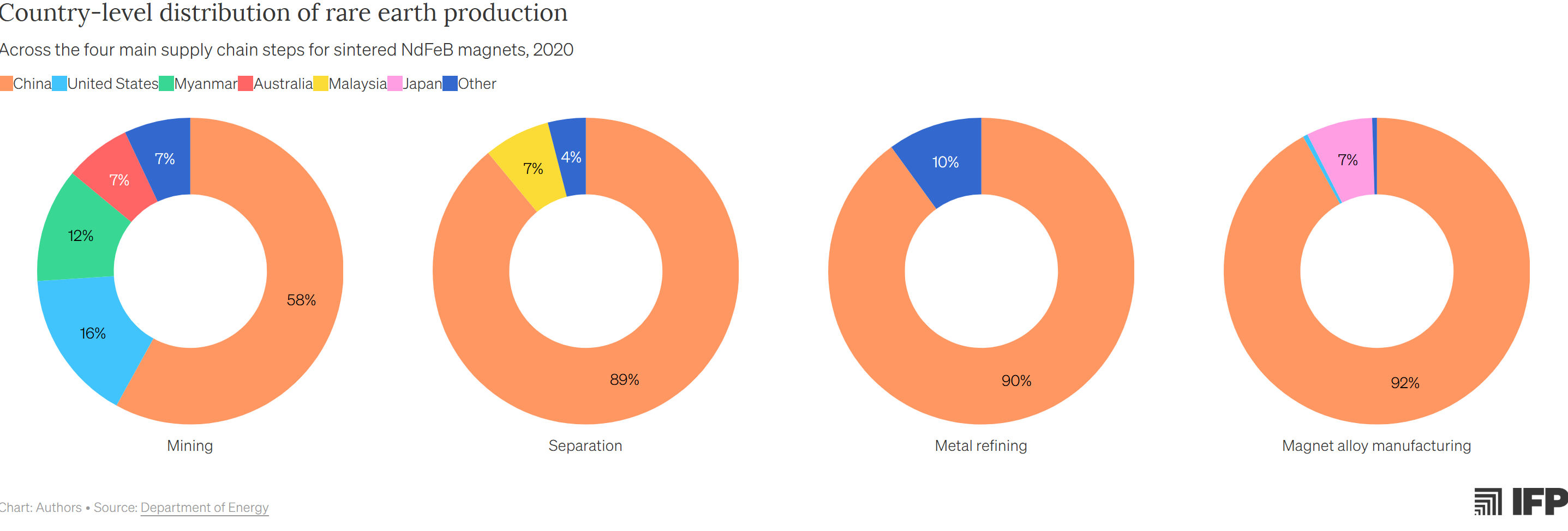

Chronic under-investment outside of China is not just a feature of mining. It’s also acute in the “midstream,” the phase of the refinement process when raw ore is processed into usable metal. Today, more than 90% of global rare-earth separation is controlled by China. Nickel tells a similar story: the US has no primary nickel refining capacity, while state-directed build-outs in China and Indonesia now dominate global processing capacity. Aluminum smelting has withered too — primary production in the US is down approximately 80% since 2000, with only a handful of smelters left. These are capital-intensive, long-payback assets, and in an era of financial buyers focused on extracting cash from legacy facilities, the result has been a hollowed-out processing base and increasingly fragile cash flows.

The Mountain Pass mine in California, which was recently part of a multi-billion-dollar deal between the Department of Defense and parent company MP Materials, illustrates this story well. From the 1990s through the mid-2010s, China’s rise as the dominant producer of rare earths steadily undercut the Mountain Pass mine. Chinese state-backed expansion drove prices down just as Mountain Pass faced rising costs, forcing its shutdown by 2002. When Beijing imposed export quotas and briefly cut shipments to Japan in 2010, prices spiked and Molycorp revived the mine. But renewed Chinese production, smuggling, and the 2015 World Trade Organization ruling ending quotas caused another price collapse. Saddled with debt and costly processing upgrades, Molycorp went bankrupt, and Mountain Pass again fell idle — until 2017, when a new consortium, MP Materials, acquired the site and restarted operations.

As it stands, uncertainty about future prices is irreducible, and can render expected revenues uneconomical as investment matures into production. Therefore, it’s entirely rational for producers and processors to err on the side of under-investment, especially given the compounded uncertainty from our clunky permitting process.

Given the environmentally sensitive nature of mining and processing, we should expect intensive review to permit projects. But that review should be predictable and timely, not uncertain and cumbersome. But even when permits are issued, projects can fall into a "litigation doom loop" that ties up capital for years or even over a decade.

Although it ultimately opened, the Coeur Kensington Gold Mine in Alaska endured a 17-year delay from litigation before production could begin. Similarly, the Rosemont Copper Mine in Arizona faced 5 years of litigation on environmental grounds before being blocked. The project began its regulatory process in 2008 and the United States Forest Service issued a Record of Decision in 2017, only to have environmental groups challenge the approval on multiple fronts, including NEPA’s scope and the validity of mining claims under the 1872 Mining Law. A federal judge overturned the approval in 2019, and the Ninth Circuit upheld that decision in 2022, holding that the Forest Service could not approve a mine plan that relied on the use of adjacent federal lands for waste rock or tailings[2] disposal unless the mining company demonstrated valid mineral rights on those lands. After 14 years of investment, a project that had undergone over a decade of environmental review was blocked.

The Ninth Circuit ruling injected further uncertainty into the permitting of American mining projects. Breaking with decades of agency practice that had allowed miners to use nearby federal lands for waste rock, tailings, and processing facilities as part of a single integrated mine plan, the Ninth Circuit ruled that companies must prove they’ve discovered minerals on each parcel of federal land that they would use for mining-related infrastructure, even if those lands were not intended for extraction.

This ruling has made it far riskier and more time-consuming to construct and permit viable mine sites. In practical terms, large-scale projects, which almost always need space beyond the region where ore is mined, now face legal vulnerability and financing uncertainty until every surrounding claim is validated. This process can take years and depends on discretionary determinations by the Bureau of Land Management. The Ninth Circuit decision thus chilled new investment in domestic mineral development.

Data from the Breakthrough Institute shows that the average mining project [faces]https://thebreakthrough.imgix.net/A-Comprehensive-Analysis-of-NEPA-Litigation_v6.pdf) more than two years of uncertainty between the challenge and a judicial decision, even before knowing whether litigation will overturn years of work. When challenges succeed, they often send agencies back to square one, restarting environmental analyses that can consume another half-decade or more.

Under our current system, capital from investors and lenders sits idle, and viable projects die — not from resource constraints or economic weakness, but from litigation risk that no financial model can predict. By contrast, Chinese policy has been marked by a consistent, holistic, and decades-long strategy to seize control of the global marketplace for critical minerals.

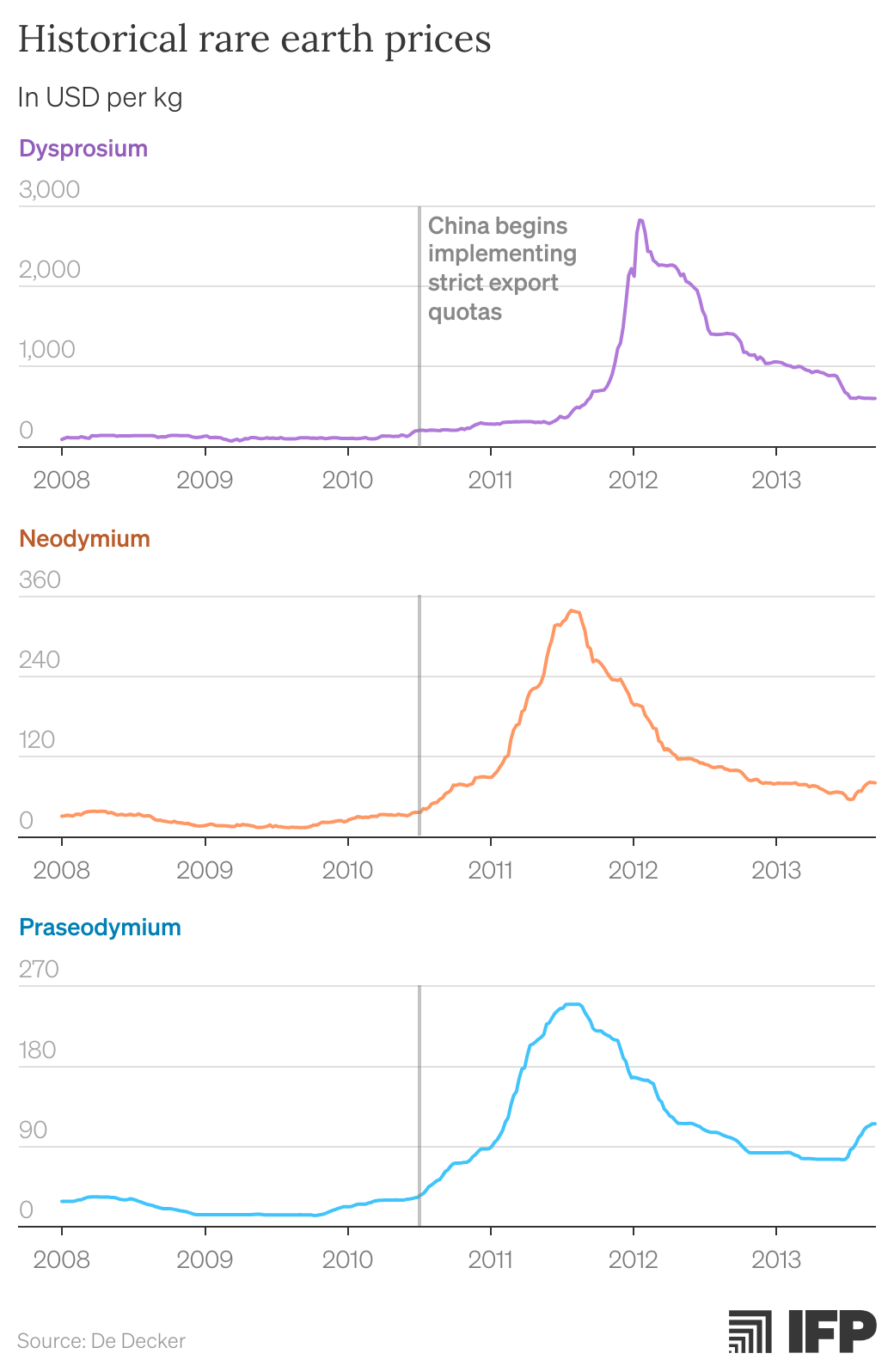

China’s grip on the rare earths market, and critical minerals market writ large, cannot be overstated. China leads production for many critical minerals — over 65% of rare earth mineral production in 2023 was in China, and one forecast estimated that 97% of mined lithium in Africa would come from Chinese-owned projects. Its supremacy is even more profound in processing — China processes 58% of lithium, 70% of cobalt, and over 90% of the world’s rare earths.

China’s dominance didn’t happen by chance — it is the result of a targeted, purposeful, and multi-pronged strategy:

Beginning in the 1990s, Beijing made a strategic choice to turn processing, a higher-value chain activity, into an anchor of its industrial base. State-directed capital poured into processing facilities across Inner Mongolia (particularly near Baotou) and Jiangxi (near Ganzhou) provinces. These investments were often unprofitable at first, but they built technical expertise and economies of scale that were difficult for foreign competitors to match.

Subsidies covered energy and labor costs, while state banks offered cheap credit and loan forgiveness to strategic producers. The seemingly insatiable thirst for commodities arising from China’s infrastructure boom in the late 1990s and early 2000s drove major increases in investment — only to run into a generational financial crisis that killed near-term demand. The result was an enormous overhang of capacity that depressed global prices, driving Western processors into bankruptcy and forcing the closure of financing desks at financial institutions. This was exacerbated by well-intentioned reforms following the crisis such as the Volcker Rule, Basel III, and Dodd-Frank that pushed capital out of Western commodity markets.

After consolidating production and processing, Beijing pursued a less visible but equally powerful lever of control: market infrastructure. China built and now dominates the exchanges, benchmarks, and trading systems through which prices for critical minerals are discovered. The Baotou Rare Earth Products Exchange, Shanghai Metals Market, and a proliferation of other entities across the country gave China not just production control, but the ability to shape price discovery and market liquidity to its advantage. The announcement of the Baotou Rare Earth Products Exchange explicitly stated a purpose of increasing China’s pricing power for rare earths.

In response, liquidity dried up across Western commodity markets. For example, Shanghai’s nickel contract began to overtake the London Metals Exchange (LME) in volume just one year after its launch. Recent reporting suggests that the Shanghai Futures Exchange is looking to open their contracts to “institutional investors” to bring in more liquidity to their market, a worthy challenger in light of the LME nickel market’s dysfunction over the past decade.

The result was a system in which transactions were opaque, bilateral, and state-distorted. This weakened Western commodity finance, and exposed miners and processors to unhedgeable price swings. As prices collapsed, assets across Africa, Latin America, and Southeast Asia became distressed — creating the opening for the third phase of China’s strategy.

Through a combination of policy banks, state-owned enterprises, and nominally private firms operating under strategic guidance, Beijing has built a web of control across critical mineral supply chains. With the ability to crash prices and depress asset values, China could become the distressed asset investor to exert control across the value chain.

For example, in 2016, years of depressed cobalt and copper prices had slashed the value of Freeport’s (an American mining company) majority stake in the Tenke Fungurume copper-cobalt mine in the Democratic Republic of Congo. China Molybdenum Co. pounced, purchasing the asset for $2.65 billion. The acquisition gave Beijing control over one of the world’s largest sources of cobalt — a mineral essential for lithium-ion batteries — and deepened its dominance in the global battery-materials supply chain. Though billed as a commercial transaction, the deal reflected a deliberate state-aligned strategy: secure long-term access to critical minerals through overseas acquisitions, often in developing economies and often timed when market conditions made assets cheap.

The Freeport transaction was part of a broader pattern. Chinese firms expanded into lithium brine operations in Latin America, nickel smelters in Indonesia, and mines [all across Africa]https://www.wilsoncenter.org/blog-post/addressing-chinas-monopoly-over-africas-renewable-energy-minerals). Each investment was financially defensible on its own terms, but collectively they revealed a coordinated effort to control the critical mineral value chain and lock in downstream manufacturing advantages for batteries, magnets, and clean-energy technologies.

With market infrastructure in place, China was well-placed to execute a holistic, state-driven strategy to extend its control in these key markets. China plays the long game — accepting commodity sector losses to undercut rivals and then securing dominance in high-value exports like electric vehicles. With price signals determined through Chinese market dynamics strategy, American and allied producers struggle to compete. In an industry already characterized by low margins, China’s price fixing stifles private investment in innovative technologies where the US has a competitive edge, such as direct lithium extraction. With the entire world subject to its chokepoints, China is well-equipped to restrict access to critical materials to achieve its policy goals. With this month’s sweeping new export controls, this strategy is now well underway.

With market infrastructure in place, China was well-placed to execute a holistic, state-driven strategy to extend its control in these key markets. China plays the long game — accepting commodity sector losses to undercut rivals and then securing dominance in high-value exports like electric vehicles. With price signals determined through Chinese market dynamics strategy, American and allied producers struggle to compete. In an industry already characterized by low margins, China’s price fixing stifles private investment in innovative technologies where the US has a competitive edge, such as direct lithium extraction. With the entire world subject to its chokepoints, China is well-equipped to restrict access to critical materials to achieve its policy goals. With this month’s sweeping new export controls, this strategy is now well underway.

China’s rare earth controls are one of the most expansive sets of export controls any country has ever issued. Rolled out in two stages with an initial tranche on April 4, 2025 and a dramatic escalation on October 9, the rules comprehensively control exports to every country in the world of both rare earth products and the manufacturing capabilities needed to make these products. Some controls are already in effect, while others become effective in stages on November 8 and December 1.[3]

The controls on rare earth products cover rare earth elements (REEs) and metals, alloys, oxides, targets, and magnets containing them. They apply to both Chinese-origin products and foreign-made products:

The controls on rare earth manufacturing cover rare earth and magnet production equipment, know-how, and persons support. They apply to global exports to specific Chinese-origin items, and to all Chinese exports and persons support for overseas rare earth and magnet production.

Given their global scope, these controls could significantly impact global high-tech supply chains. The controlled rare earth products are used across much of global high-tech industry, including in areas like motors, robotics, electric vehicles, drones, wind turbines, hard disk drives, displays, datacenter cooling, precision servos, radars, sensors, and semiconductor manufacturing equipment and materials for making all types of semiconductor chips, including AI chips and defense electronics. The only exceptions to the controls are for humanitarian relief, basic science, and public domain technologies.[12]

However, the scale of impact is difficult to predict until China begins implementing licensing policies. The Chinese government notes that the "controls are not export bans,” and that “licenses will be granted for eligible applications.” While the rules themselves do not articulate licensing policies for all categories of exports, they do say that licenses will be denied for overseas military users, end-users on watch lists and export controls (as well as subsidiaries and branches in which they hold a 50% stake), weapons of mass destruction, military end-uses, and terrorist purposes. They also specify a case-by-case However, the scale of impact is difficult to predict until China begins implementing licensing policies. The Chinese government notes that the ”controls are not export bans,” and that “licenses will be granted for eligible applications.” While the rules themselves do not articulate licensing policies for all categories of exports, they do say that licenses will be denied for overseas military users, end-users on watch lists and export controls (as well as subsidiaries and branches in which they hold a 50% stake), weapons of mass destruction, military end-uses, and terrorist purposes. They also specify a case-by-case licensing policy for exports related to R&D and production of advanced logic chips (≤14 nanometer) and advanced NAND memory chips (≥256 layers), semiconductor manufacturing equipment and materials for the above semiconductor chips, and R&D for AI with potential military applications.

China is likely pursuing multiple goals with its rare earth controls. Three likely motivations include negotiation leverage in trade talks, retaliation to American restrictions, and degrading American and allied technological capabilities. A fourth, more speculative motivation is that China is using these controls to entrench its dominance in downstream rare earth-dependent manufacturing supply chains. More specifically:

Rapidly rebuilding America’s critical mineral capacity must match the depth and intentionality of China’s strategy. This strategy must rest on four pillars:

The foundation of America’s strategy should be building a truly competitive ecosystem that rewards innovation rather than entrenching incumbents. China’s dominance emerged not from selecting single champions but from orchestrating intense domestic competition across dozens of firms. Companies like CATL rose to the top by out-innovating their peers under policy regimes that distributed subsidies broadly before consolidating support behind proven winners. Similarly, one of the great successes of Operation Warp Speed was the creation of not one, but multiple competitors in the market for mRNA vaccines offering distinct technologies, from upstarts like Moderna to established firms like Johnson & Johnson.

Startups across the US demonstrate the breadth of America’s innovative potential, but they need an even playing field. For example, Phoenix Tailings uses “water and recyclable solvents to collect oxidized metal, then puts the metal into a heated molten salt mixture and applies electricity” to produce pure rare-earth alloys, using only 5% of the energy of traditional processes and with zero toxic byproducts. Meanwhile, Alta Resource Technologies developed a technology in partnership with Livermore National Lab that uses protein-based molecular separation to extract rare earths from waste and low-grade feedstocks, turning recycled electronics into domestic supply. To be clear, neither are proven as viable competitors at scale. But, with support, both companies could compete in the ecosystem.

But innovation cannot thrive without stable market plumbing. China’s creation of domestic metals exchanges, like the Shanghai Metals Market, gave it control over price discovery and liquidity. The United States must build its own market infrastructure. Large-volume commodities such as lithium could support physically settled futures contracts. Thinner markets like rare earths including scandium or terbium could be supported with lower-cost mechanisms where end purchasers bid for American products. Metalshub’s spodumene model offers a path forward for smaller metals — monthly auctions that create transparency and true price discovery ex-China. American-based exchanges or other intermediaries could anchor this infrastructure, supported by guaranteed offtake and warehousing capacity.

The Trump administration appears to understand the necessity for a creative approach, using the full flexibility of the Defense Production Act’s Title III authorities to structure the MP Materials deal. Rather than defaulting to just grants or loans, the Pentagon deployed an innovative mix of lending, equity, warrants, guaranteed purchases, and a price-floor contract to stabilize returns and attract private co-investment. This expansive interpretation of the DPA’s “make provision” clause filled key gaps in the American industrial-policy toolkit, created a precedent for future equity-like interventions, and demonstrated that government financing can be both counter-cyclical and self-recouping — lowering future transaction costs and broadening the policy frontier for strategic supply-chain investments.

But the deal also carries risks. By anointing MP Materials as America’s national champion for finished rare earth magnets without an open contest, the government short-circuited the competitive process that China itself used to cultivate industrial leaders like CATL. This approach risks locking the US into a single, potentially underperforming path while sidelining potential innovators such as Niron Magnetics and Vulcan Elements that could deliver breakthroughs in cost or technology. The deal indexes its price protections to China’s Asian Metal Market index — hardwiring America’s fiscal exposure to a benchmark shaped by Beijing’s policy choices and market structure. This reinforces dependence on China’s pricing power, rather than eroding it.

Given the risks of politicization, it is imperative that these tools be deployed by government actors with the technocratic capabilities and independence necessary to have credibility with businesses, markets, and the broader public. In the short-term, that means the Trump administration should design programs or facilities that take a neutral view of the ecosystem and reward all competitors that can achieve predetermined objectives.

In the longer-term, Congress must authorize a new reserve entity that can deploy these tools within an independent and technocratic structure. To date, Representative Rob Wittman of Virginia has proposed the most promising version, which takes an approach that would provide leverage to intermediaries to provide liquidity to the market. It’s a strong model that can be built on.

A Strategic Resilience Reserve (SRR), as previously proposed by Employ America and Daleep Singh, could carry this out. Modeled on the Federal Reserve, the SRR would operate independently to stabilize commodity markets using a suite of financial and physical tools. It could:

With a robust toolkit to build liquidity and market infrastructure, an SRR could support the development of a competitive ecosystem whereby individual companies like MP Materials and others can out-innovate and out-compete their Chinese rivals.

A coherent American-led coalition on critical minerals could build a robust supply chain exclusive of China. Countries with deep demand, like the United States and India, should take the lead in guaranteeing purchase commitments and aggregating demand for critical inputs. Nations with robust financial systems, such as Japan, can specialize in developing hedging and insurance products that reduce price risk. Countries with limited reserves like South Korea, can provide low-cost financing and technology support to de-risk upstream projects.

Japan’s success supporting Australia’s Mount Weld rare earths mine provides a proven model. When Beijing restricted exports after its 2010 dispute with Japan, Tokyo responded through the Japan Organization for Metals and Energy Security, which financed Lynas’s mine and secured an offtake agreement with Sojitz. That partnership ultimately enabled Lynas to expand downstream processing, including in Texas with U.S. Department of Defense support. With American leadership, these arrangements should be institutionalized through multilateral platforms that pool risk, coordinate investment, and reduce exposure to Chinese coercion.

Traditional tools such as Development Finance Corporation lending and export credit guarantees remain essential, but they are insufficient on their own. To close coordination gaps, the United States should champion an allied framework for guaranteed offtakes, price floors, and stockpiling agreements that collectively stabilize upstream investment. A coalition built on transparent, rules-based commitments rather than ad hoc deals can give producers the certainty they need to invest at scale.

The third pillar is reforming the permitting process that ties up capital and creates a litigation doom loop that strangles projects before they begin. Addressing it doesn’t mean weakening substantive environmental standards — just reforming the procedural gauntlet and litigation attack surface that can make projects impossible for investors to support. This again mirrors the proven success seen in initiatives like Operation Warp Speed: the reform of regulatory hurdles to vaccine testing and approval preserved public safety while massively accelerating technological progress.

Congress has shown it understands the stakes when national security is on the line. Recognizing that semiconductor supply chains could not wait, lawmakers exempted many categories of CHIPS Act-funded fabs from NEPA review, accelerating their construction. Most importantly, it has not meant weakening the substantive environmental protections that keep communities safe. As with any project, the fabs must comply with the Clean Air Act, Clean Water Act, Endangered Species Act, and local regulations.

Creating narrow litigation exemptions for purely procedural environmental laws — like NEPA and the Administrative Procedure Act — would offer a similar balance for critical minerals. These statutes govern process, not outcomes; they ensure agencies follow the right steps but do not themselves set environmental standards. Lawsuits under these procedural regimes can drag on for years even when projects fully comply with substantive protections. Tailored exemptions that preserve substantive compliance while limiting endless procedural challenges would give investors and agencies alike greater certainty. The result would be faster permitting, without cutting corners on environmental quality.

Congress should also pass the Mining Regulatory Clarity Act to restore a legal standard that governed for decades before the Rosemont decision. As discussed earlier, for nearly half a century, agencies allowed miners to use adjacent federal lands for tailings, waste rock, and processing facilities as part of an integrated mine plan. Rosemont upended that settled understanding, injecting crippling uncertainty into mine financing and permitting. The Mining Regulatory Clarity Act would return the law to its long-standing interpretation, enabling developers to design efficient, environmentally responsible mine plans without fear that a single procedural ruling could invalidate years of review.

Finally, broader permitting reform must place reasonable limits on judicial discretion that allows procedural challenges to stretch timelines indefinitely. The bipartisan SPEED Act, introduced by Representatives Bruce Westerman and Jared Golden, is an important step in that direction. It would streamline timelines for judicial review, set firm deadlines for court decisions, and prevent endless remands that send agencies back to step one. These reforms would not constrain environmental enforcement, they would simply ensure that disputes are resolved in a timely manner. Combined, these measures would restore predictability, unlock investment, and uphold the integrity of America’s environmental standards while actually enabling the clean-energy future those laws were meant to support.

The Administration should recommit to American export controls as non-negotiable national security tools. It is tempting to relax American export controls on semiconductors and other technologies in exchange for China to relax its own rare earth controls. However, it is precisely the US government’s willingness to put export controls on the negotiating table that has increased the incentive for Chinese retaliation. The US government should stay the course on export controls on semiconductors and other strategic technologies, given the importance of these controls for AI and security competition with China.

The Administration should instead negotiate in the economic and trade domain. For example, the US government can offer reductions in American tariffs and other trade-related measures unrelated to national security, to gain Chinese concessions. Even if the US government chooses to use export controls as leverage, at most these should be in areas explicitly communicated as for negotiation leverage, and clearly distinguished from non-negotiable national security-motivated restrictions.

The comprehensive nature of the Chinese controls have more deeply exposed a longstanding vulnerability and have taken the US and the rest of the world past the point of no return. As such, there is no choice but to collectively pursue ambitious policy to de-risk rare earth supply chains from China.

In the rare earths industry, miners mine raw rare earth ore, while processors perform the complex chemical separation and purification necessary to isolate individual rare earth elements from the ore. ↩︎

Tailings are the waste material left over after the process of separating valuable minerals from crushed rock during mining. ↩︎

See China’s rare earth export control announcements no. 18, 56, 57, 61 (translation), and 62. On October 9, China also issued controls on superhard synthetic diamonds (no. 55), lithium ion batteries, cathode materials, and graphite anode materials (no. 58), but they are not discussed in detail here because they implicate products less related to REEs. ↩︎

Metallic samarium, metallic dysprosium, metallic gadolinium, metallic terbium, metallic lutetium, metallic scandium, metallic yttrium, samarium-cobalt alloys, terbium-iron alloys, dysprosium-iron alloys, terbium-dysprosium-iron alloys, dysprosium oxide, terbium oxide. ↩︎

Target materials that contain samarium, gadolinium, terbium, dysprosium, lutetium, scandium, yttrium. ↩︎

Samarium cobalt permanent magnet materials, neodymium permanent magnet materials that contain terbium, neodymium permanent magnet materials that contain dysprosium, and parts, components, and modules that contain the above mentioned materials. ↩︎

Centrifugal extraction equipment, intelligent continuous impurity removal and precipitation equipment, rare earth roasting kilns, extraction tanks, ion adsorption equipment, precipitation crystallization reactors (and related parts and components), rare earth resistance furnaces, equipment for the electrolysis of rare earth metals, rare earth electrolytic cells, vacuum induction reduction furnaces, vacuum carbon tube furnaces, Czochralski rare earth crystal growing furnaces, crucible-drop method rare earth crystal growth furnaces, rare earth permanent magnet vacuum induction casting furnace (and related parts and components), rare earth permanent magnet hydrogen crushing furnace (and related parts and components), rare earth permanent magnet jet mills, rare earth permanent magnet forming presses, automatic hot pressing equipment, cold isostatic pressing machines, rare earth permanent magnet vacuum sintering furnaces, grain boundary diffusion equipment, and vertical kilns. ↩︎

Bastnaesite, monazite, and ion adsorption type rare earth minerals. ↩︎

Technical information and know-how for rare earth mining, smelting and separation, metal smelting, magnetic material manufacturing, and recycling and utilization of rare earth secondary resources, and their carriers, and assembly, commissioning, maintenance, repair, and upgrading of production lines for rare earth mining, smelting and separation, metal smelting, magnetic material manufacturing, and recycling of rare earth secondary resources. ↩︎

Rare earth mining, smelting and separation, metal smelting, magnetic material manufacturing, or rare earth secondary resource recycling activities. ↩︎

Chinese citizens, legal persons and unincorporated organizations. ↩︎

The license requirements for certain metals, alloys, oxides, target materials, and magnets containing certain REEs do not apply for exports involving humanitarian relief such as emergency medical treatment, response to public health emergencies, and natural disaster relief. Additionally, the license requirements for technical information and know-how, end-use controls, and persons support do not apply to technologies already in the public domain, involved in basic scientific research, or necessary for ordinary patent applications. ↩︎